Top FRP Pultruded Profile Manufacturers in Oman | SV Composites

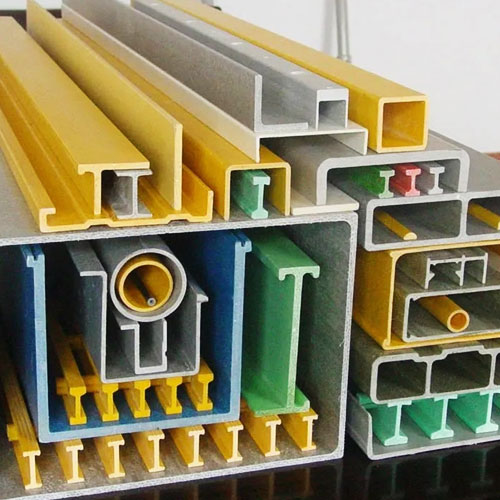

SV Composites & Engineering Pvt Ltd is leading FRP pultruded profile manufacturers in Oman, suppliers and exporters in Oman, this cyclical pulling and curing process provides homogeneous cross-sections of profiles, the highest strength-to-weight ratio, and better corrosion resistance. an FRP (Fiberglass Reinforced Plastic) pultruded profile is a composite structural shape of continuous length made by a sophisticated technique known as pultrusion.

FRP Pultruded Profile Manufacturers in Oman

FRP pultruded profile exporters in Oman have the value of international standards of quality, proper packaging, and ideal care of international logistics so that we export next-generation composite materials to the international corners of the world. Our FRP Pultruded Sections is to provide these light-weight, high-strength, and low-maintenance profiles to infrastructure, industry, and building construction activities in various foreign countries.

As FRP pultruded profile suppliers in Oman provide a wide variety of stock shapes (e.g., angles, I-beams, channels, rods, tubes) and specialty shapes, all with solutions for a wide variety of structural, electrical, and corrosive environments. It is our job to specify the correct type of profile and resin system to fulfill particular client requirements and provide maximum structural resistance and durability to differing environments.

Types of FRP Pultruded Profile

Being as well known FRP pultruded profile manufacturers in Oman, it has different types as per industries uses which has given below.

- FRP Specialty and Custom Profiles: Engineered to exact design parameters for specific applications, Pultrusion Profiles may have very complex cross-sections engineered as individual machine components, architectural components, or transit assembly components.

- FRP I-Beams and Wide Flange Beams: Facsimile style profiles of typical steel I-beams, these are extremely robust for platforms, walkways, and structural frame. Corrosion-resistant and heavy-load carrying, FRP Square Pultruded Profile are optimum for harsh industrial uses.

- FRP Angles and Channels: Employed as bracing, framing, ladder rungs, and other supporting structure members, Frp Pultruded Profile Products profiles offer general-purpose applications in FRP pultruded profile suppliers in Oman connection and strengthening.

- FRP Tubes (Round, Rectangular, Square): Round, rectangular, and square tube shapes are utilized in the framing of handrails, electrical conduit, cross-bracing, and lightly framed structural members. Its encasement construction provides the internal liquids or wiring with extra protection, and the non-conductive nature is a bonus in case electrical components are involved.

- Grey Frp Pultruded Profile: Thick pultruded materials that are typically employed as dowel bars, support rods, or electrical insulation parts. FRP Pultruded Profiles work best to utilize in accurate Standard Structural Pultruded Sections applications in which they need to be rigid due to Composite Profiles high tensile strength and dimensional stability.

Technical Specification of FRP Pultruded Profile

We have added below a technical sheet of FRP pultruded profile in Oman that provides more technical information such as:

| Feature | Specification (Typical) |

| Material | Pultruded Fiberglass Reinforced Polymer (FRP) with Isophthalic, Vinylester, or Phenolic Resins |

| Reinforcement | E-Glass Fibers (rovings, mats, veils) |

| Strength | High Longitudinal Tensile (>200 MPa), Flexural (>250 MPa), and Compressive Strength |

| Weight | Lightweight (1.7 - 2.0 g/cm³), approx. 1/4th of steel |

| Corrosion | Excellent Resistance to Acids, Alkalis, Salts, & Chemicals |

| Electrical | Non-Conductive, High Dielectric Strength (>30 kV/mm) |

| Thermal | Wide Operating Temp (-50°C to +150°C), Low Thermal Expansion, High HDT |

| Fire Retardancy | Self-Extinguishing, Low Flame Spread (ASTM E-84 Class 1 or better) |

| UV Resistance | High (Integrated UV Inhibitors) |

| Water Absorption | Very Low (< 0.5%) |

| Maintenance | Zero Maintenance (No Rusting, Painting Required) |

| Shapes | Angles, Channels, I-Beams, Tubes, Rods, Flat Bars, Custom |

| Standards | Conforms to ASTM D3917, D638, D790, E-84, IS 12786 (Oman) |

| Color | Pigmented for lasting color |

Benefits of FRP Pultruded Profile

As FRP pultruded profile suppliers in Oman, it serves different benefits which has given below.

- UV Stability and Dimensional Stability: GRP Pultrusion Section are UV inhibitor-resistant, where they withstand degradation and color change by prolonged sun exposure expand and contract minimally with temperature change, thus providing dimensional stability.

- Improved Corrosion Resistance: In contrast to steel or aluminum, FRP pultruded profile exporters in Oman will not rust, rot, or deteriorate when exposed to aggressive chemicals, seawater, water, or severe climate, and therefore have much longer lives at lower replacement costs.

- High Strength-to-Weight Ratio: FRP profiles have the same strength as steel but weigh one-sixth of its weight, thus making it easier, safer, and less expensive to transport, handle, and install. FRP Pultruded Structures also minimizes foundation and support structure load to an absolute minimum.

- Non-Magnetic and Non-Conductive: For the same reasons why FRP Pultrusion Section are non-magnetic and non-conductive in nature, we are a proper choice to secure around near electrical machinery, substations, MRI devices, or precision equipment where conductance or magnetic interference must be evaded for safety.

- Low Maintenance and Long Lifespan: Since FRP profiles are resistant to environmental degradation, and further with minimal painting, sandblasting, or rust coating, maintenance work and cost significantly reduce during Our long lifespan.

Applications of FRP Pultruded Profile

Serve as well known FRP pultruded profile exporters in Oman, it is applicable in different sites which as given below.

- Rail and Mass Transit: FRP pultruded profile manufacturers in Oman are used in rail and mass transit vehicle structural components, overhang of a platform, signaling equipment housings, and rail structure because of FRP Section & FRP Profiles high strength, light weight, non-conductivity, and non-corrosion.

- Chemical and Petrochemical Plants: Used in platform supports, walkways, handrails, ladders, and tank support, where our chemical resistance is paramount to survive highly corrosive conditions and spillages Yellow FRP Pultruded Grating Profile.

- Water and Sewage Treatment Plants: FRP Profile Pultruting Used in walkways, clarifier mechanisms, grating, ladders, and handrail systems due to Our chlorination, water, and treatment chemicals resistance.

- Electrical Substations and Power Generation: Particularly suitable for structural framing of high-voltage equipment, cable trays, instrument supports, and safety barriers because Fiber FRP Pultruded Profiles are non-magnetic and non-conductive to ensure improved performance and safety.

- Cooling Towers: Particularly CFRP & Pultrusion suitable for cooling tower structural members, fan decks, and louvers because White Industrial FRP Profiles resist repeated exposure to water, water treatment chemicals, and high humidity.

SV Composites & Engineering Pvt Ltd is outstanding FRP pultruded profile manufacturers in Oman, suppliers and exporters in Oman from manufacturers who make such high-tech composites with precision to distributors providing diversified options and exporters serving world needs, the place of FRP pultrusion is scarcely exaggerated. Multicolor FRP Pultruded Profile built-in advantages i.e., better corrosion resistance, greater strength-to-weight ratio, non-conductivity, and low maintenance make Standard Structural Pultruded Section ready. are a material arts science breakthrough achievement that integrate unprecedented strength, durability, and versatility way beyond traditional materials in high stress applications.

Frequently Asked Questions (FAQs)

Strong, lightweight structural shapes (like angles, beams, tubes) made by continuously pulling fiberglass and resin through a heated die.

Often more cost-effective long-term than traditional materials due to durability and low maintenance.