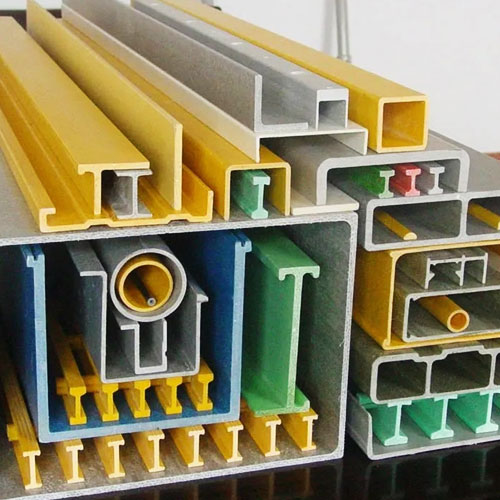

FRP Profiles

FRP Profiles are structural components manufactured using high-strength fiberglass and high-performance resins such as Epoxy, Polyester, or Vinyl Ester. Designed for superior mechanical properties and corrosion resistance, these profiles serve as a robust alternative to steel, aluminum, or wood in demanding environments. Lightweight yet extremely durable, FRP profiles offer excellent resistance to moisture, chemicals, UV exposure, and electrical conductivity.

| Material | Fiberglass Reinforced Plastic (FRP) |

| Resin Types | Epoxy, Isophthalic Polyester, Vinyl Ester (fire-retardant options available) |

| Profile Shapes | Angle, Channel, I-Beam, Box Section, Tube, Rod, Custom Extrusions |

| Length | Standard: 3m to 6m (custom lengths available) |

| Color | Grey, Green, Yellow (UV-stabilized, custom colors available) |

| Density | ~1.8 to 2.0 g/cm³ |

| Mechanical Strength | High tensile, flexural, and impact strength |

| Electrical Properties | Excellent insulation; non-conductive & non-magnetic |

| Corrosion Resistance | Excellent resistance to salt, moisture, and chemical exposure |

| Fire Resistance | Available with UL94 V-0 or ASTM E84 Class I ratings |

| UV Resistance | Yes – with UV stabilized resin or top coat |

| Thermal Range | -40°C to +120°C (varies by resin type) |

Applications

-

Structural Supports in Chemical & Petrochemical Plants

-

Walkways, Platforms, and Staircases

-

Electrical Substations & Cable Tray Supports

-

Cooling Towers & Water Treatment Facilities

-

Marine & Offshore Structures

-

Infrastructure Projects (Railways, Airports, Bridges)

-

Corrosive Zones & Hazardous Environments